Now, let’s take a deeper look at each Mozaic 3+ element in detail to understand how it contributes to making Seagate’s breakthrough areal density a reality.

Superlattice Platinum-Alloy Media

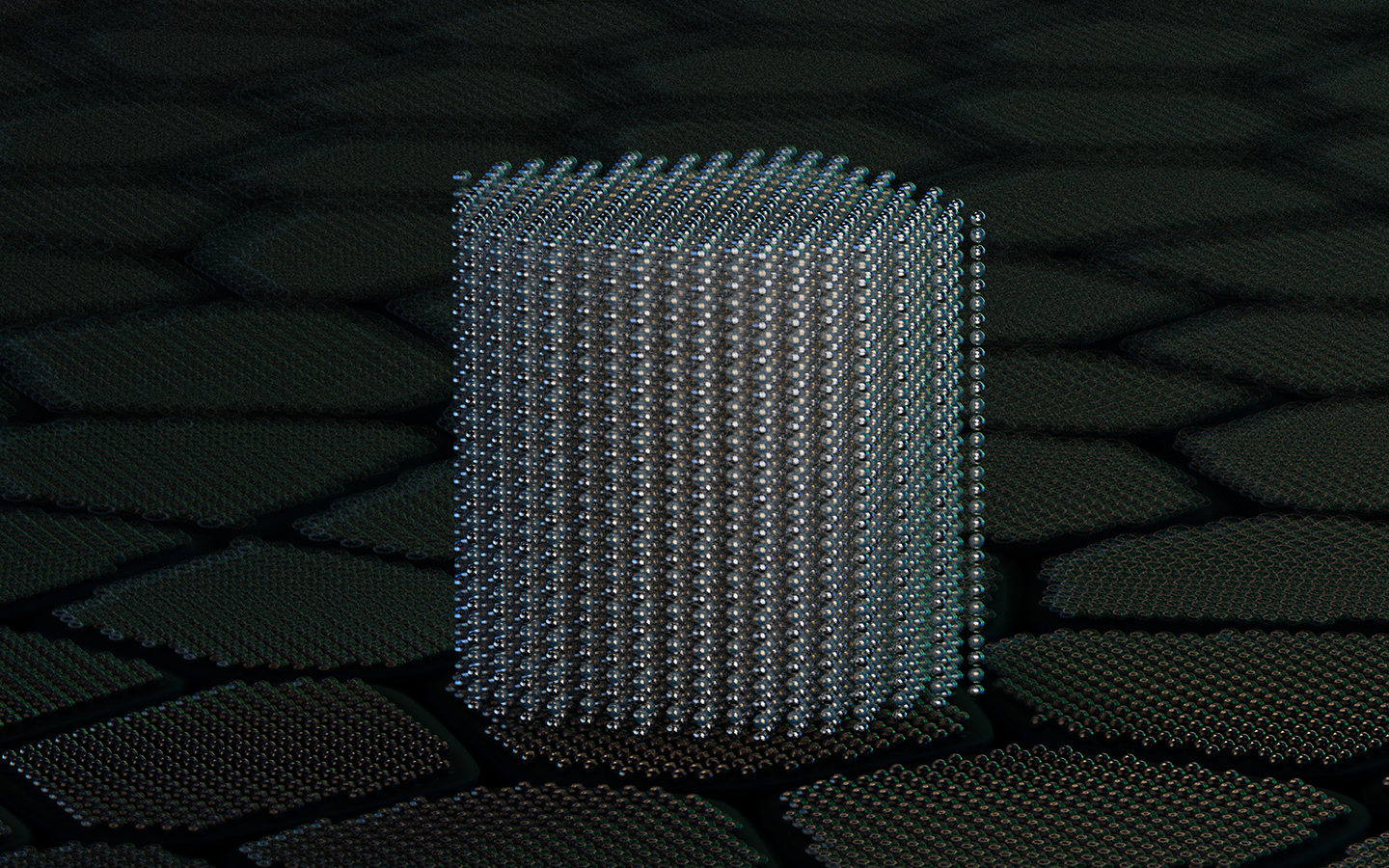

In the pursuit of increased areal density, Seagate's superlattice platinum-alloy media represents a major advancement in magnetic storage media. This breakthrough technology combats the challenge of magnetic instability at the nanoscale by making it harder to flip magnetic bits that represent data. To develop a “harder” storage layer—with higher magnetic coercivity than that found in conventional drives—Seagate engineers have crafted a superlattice structure where the precise arrangement of each atom plays a critical role.

In the Mozaic platform, where data must be stored in the form of magnetic bits that are closer together than is possible with conventional PMR hard drives, the recording media had to be rethought from the ground up. The advanced materials and structures used in Mozaic 3+ media support data writing that’s far more precise than any previous hard drive technology. The media is not simply a passive component but an active participant in the data storage process, allowing for more data storage within the same physical footprint.

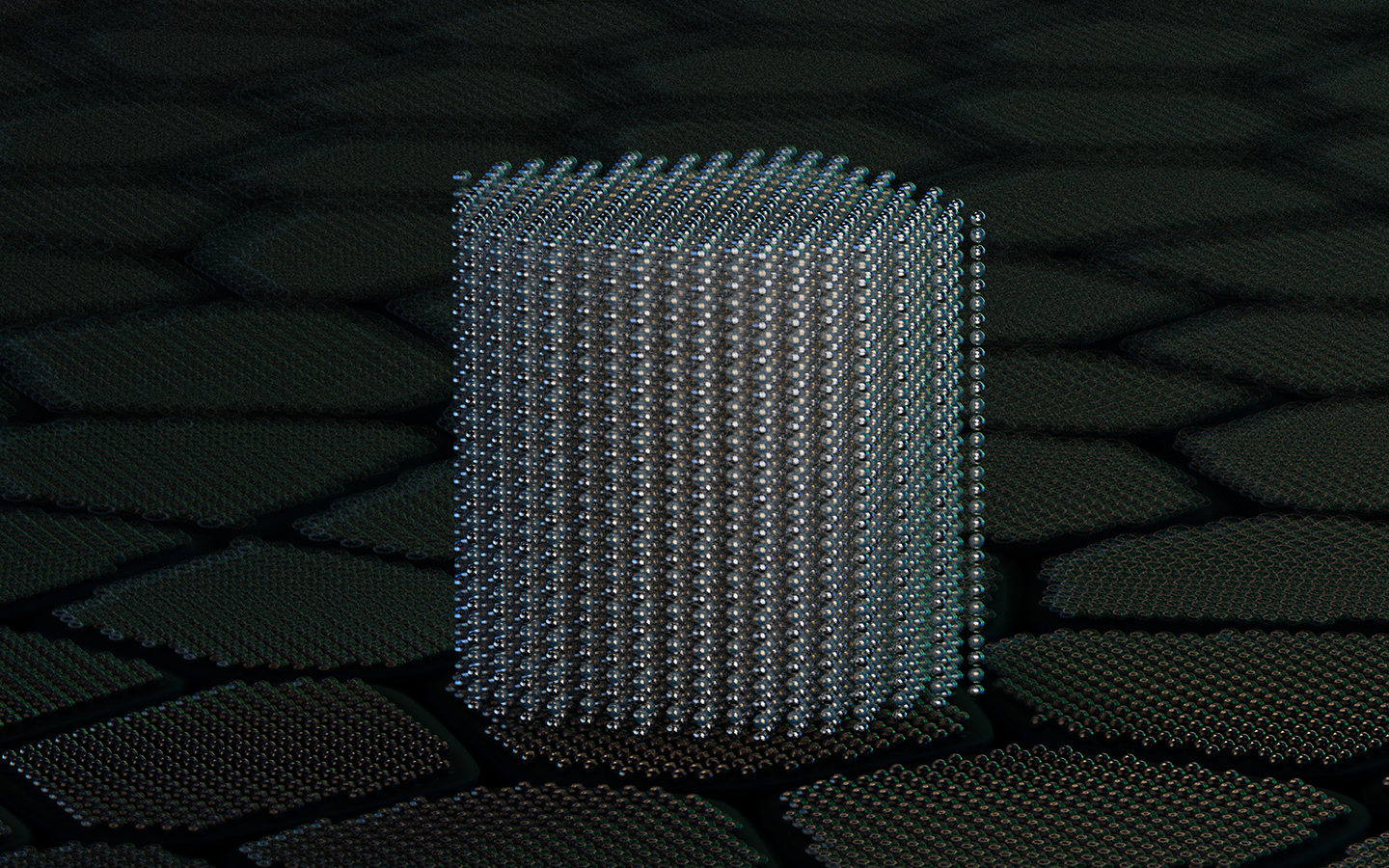

The essence of this technology lies in its use of platinum (Pt) and iron (Fe) particles, which compose the recording medium of Seagate Mozaic 3+ hard drives. Each nanoparticle, only a few nanometers in size, acts as an individual bit of data. Attaining such a fine granularity while preventing magnetic fluctuations between the bits is made possible by the media’s high magnetic anisotropy—which means that the magnetic orientation of the material tends to remain steady over time, ensuring that each bit remains stable and unaltered by the writing of adjacent data. This innovation enables Mozaic 3+ hard drives to write data with remarkable precision while preserving the integrity of surrounding data.

The recording media’s specialized magnetic alloys favor a predetermined magnetic orientation. This orientation is key to stabilizing the magnetic state of individual bits, thereby reducing their susceptibility to thermal fluctuations. Seagate’s choice of a chemically-ordered, granular iron-platinum (FePt) alloy is critical. Its high magnetic anisotropy provides the stability needed for recorded bits achieving record areal densities.

Achieving a high degree of order within the superlattice platinum-alloy media is crucial to Mozaic 3+ technology. It involves a sophisticated manufacturing process that uses epitaxial growth to deposit FePt thin films on crystalline underlayers on a special glass substrate. These underlayers serve as a template, dictating the orientation and ordering of the FePt grains during the deposition process. Subsequent annealing at high temperatures further promotes ordering in the FePt grains, leading to a phase transformation that enhances the media's magnetic properties and grain alignment.

This intricate and carefully controlled process ensures that the superlattice platinum-alloy media provides a robust, stable platform for high-density data storage. The precise arrangement of atoms within the superlattice structure is what allows Seagate’s media to contribute significantly to the increased areal density of Mozaic 3+ hard drives, marking a substantial progression in the field of data storage technology.

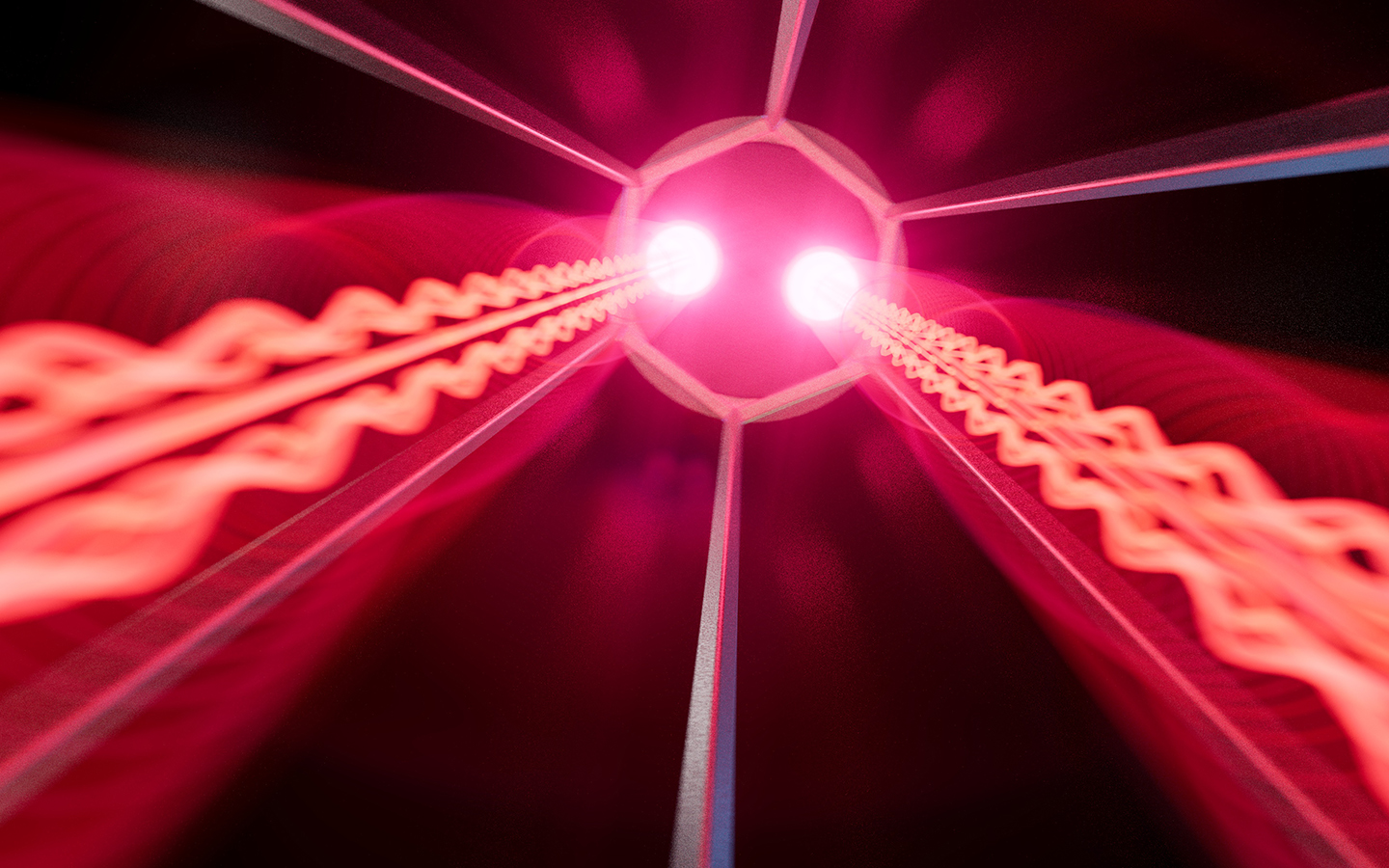

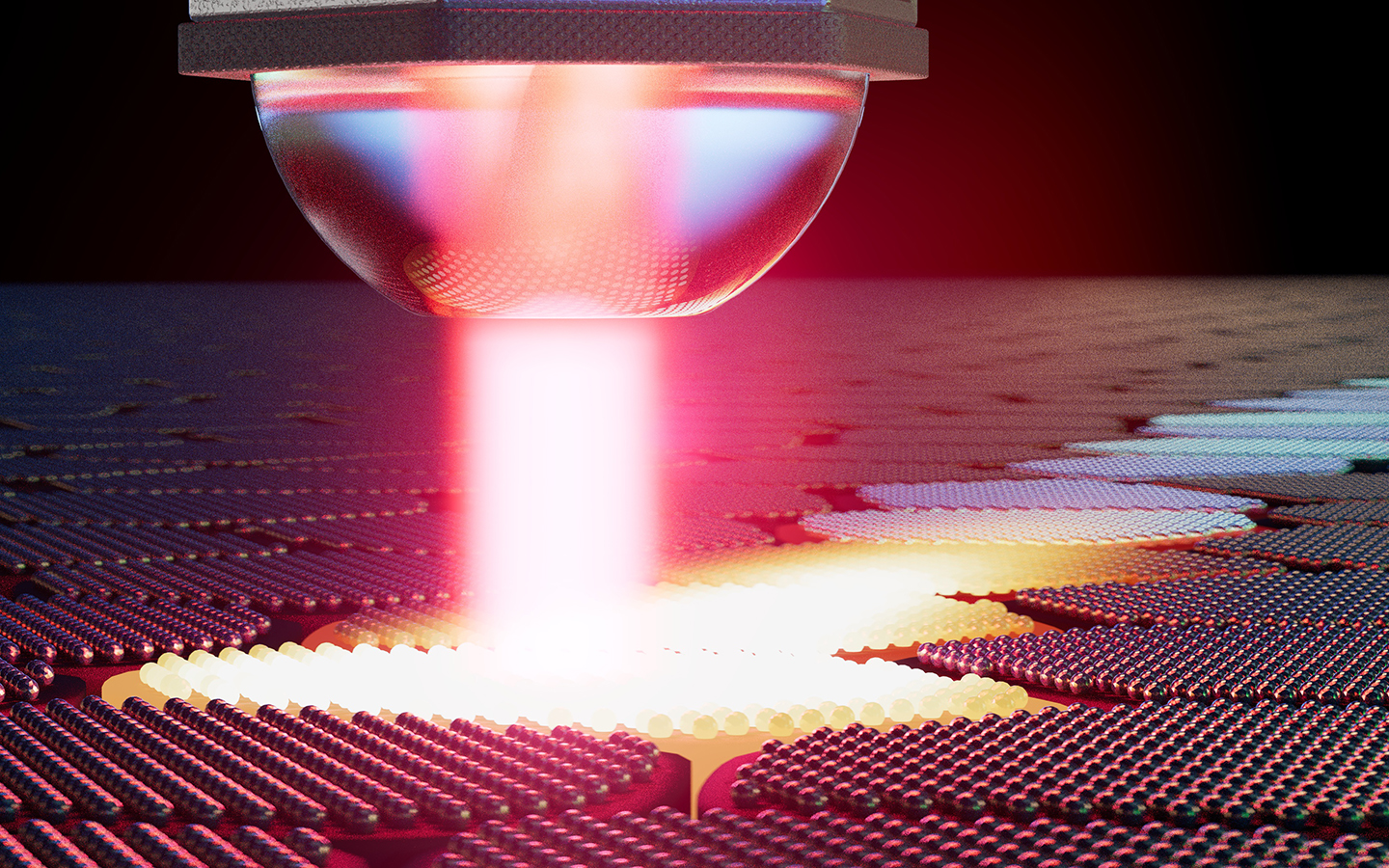

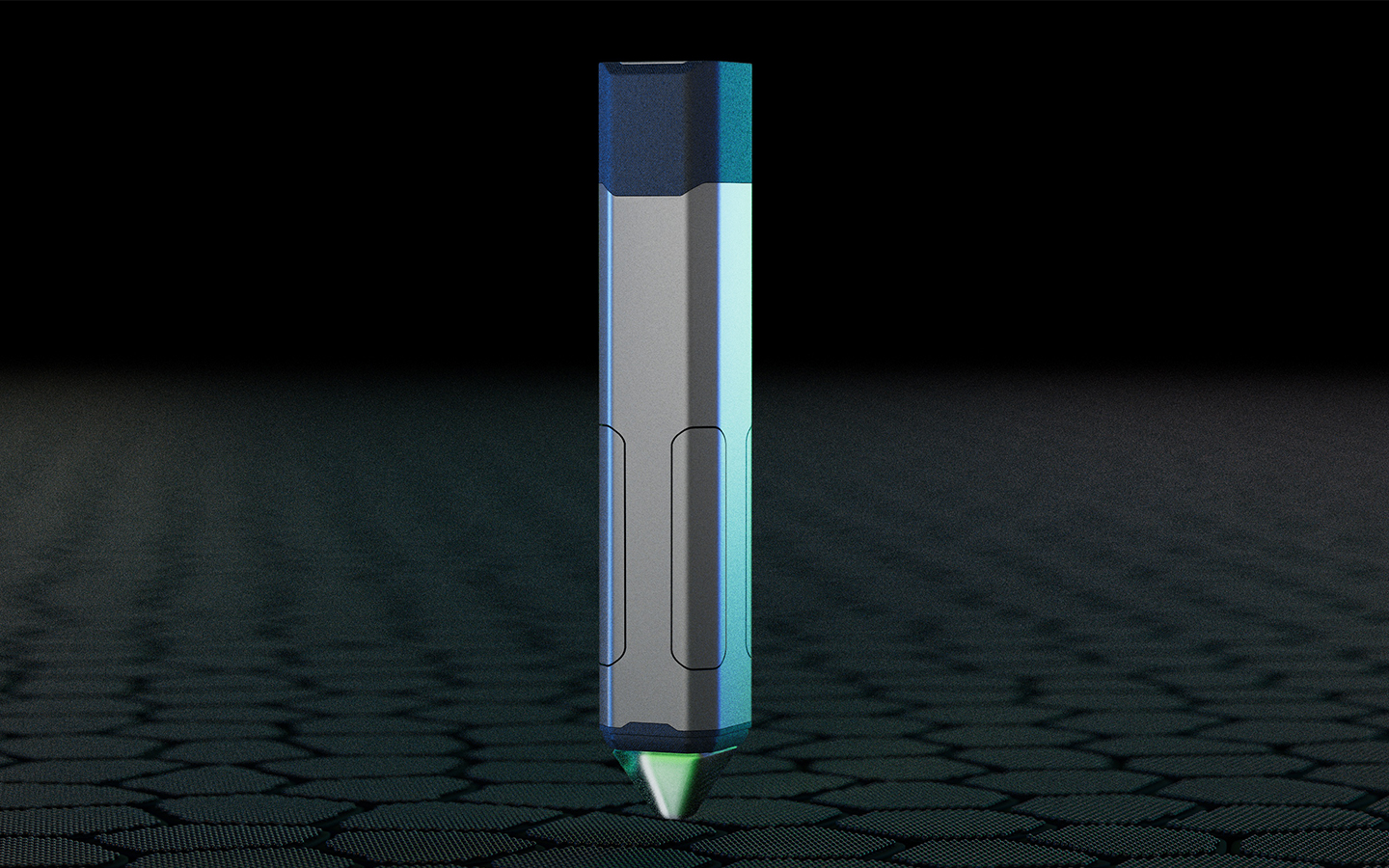

The Plasmonic Writer

Since the media is made magnetically “harder” to prevent data instability, the design requires a revolutionary writer.

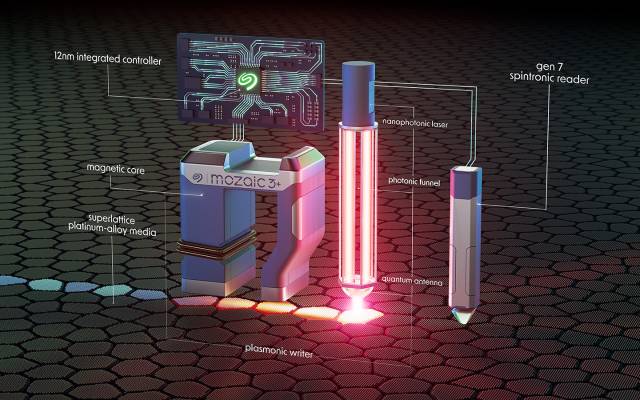

At the core of this writer's operation is the ability to precisely heat the superlattice platinum-alloy media, a task achieved by raising the temperature to over 800º Fahrenheit in less than two nanoseconds. This rapid thermal cycle is critical to Mozaic's effective recording process. The intricacies of this operation involve a laser that is precisely controlled and directed through a photonic funnel toward a quantum antenna. Together, these components create a plasmonic field that heats a focused area on the disk, preparing it so that data can be written by the magnetic core write head.

The design of the magnetic core write head has evolved to integrate seamlessly with Mozaic 3+ technology. Each refinement, from laser integration to wear resistance, has been carefully considered to enhance the effectiveness of Mozaic 3+.

Components of the Plasmonic Writer

The plasmonic writer is composed of a traditional magnetic core plus three new, groundbreaking elements, each with a specific function to enable writing within the Mozaic 3+ platform: the nanophotonic laser, the photonic funnel, and the quantum antenna.

Let’s look at each new element in detail:

Nanophotonic Laser:

The nanophotonic laser is a product of extensive innovation by Seagate to reshape the landscape of data storage technology.

The laser is the source of the energy that temporarily alters the magnetic properties of the superlattice platinum-alloy media, thus preparing the area for data writing. The precision and transience of the energy’s effect allow for the increase in the density of bits that can be stored per disk. Through sophisticated control in conjunction with the photonic funnel and quantum antenna, the laser heats only the necessary nanoparticles on the media, reducing their magnetic resistance and enabling data to be written with less magnetic field strength than would otherwise be required. The controlled heating ensures that only the bit being written is affected, maintaining the stability and integrity of surrounding data.

Seagate has innovated a cost-optimized and scalable process that integrates lasers with our advanced recording head technology. Extensive characterization has been conducted to ensure that our internally fabricated lasers maintain the same level of consistency and quality as those from other leading manufacturers, thereby creating long-term supply flexibility.

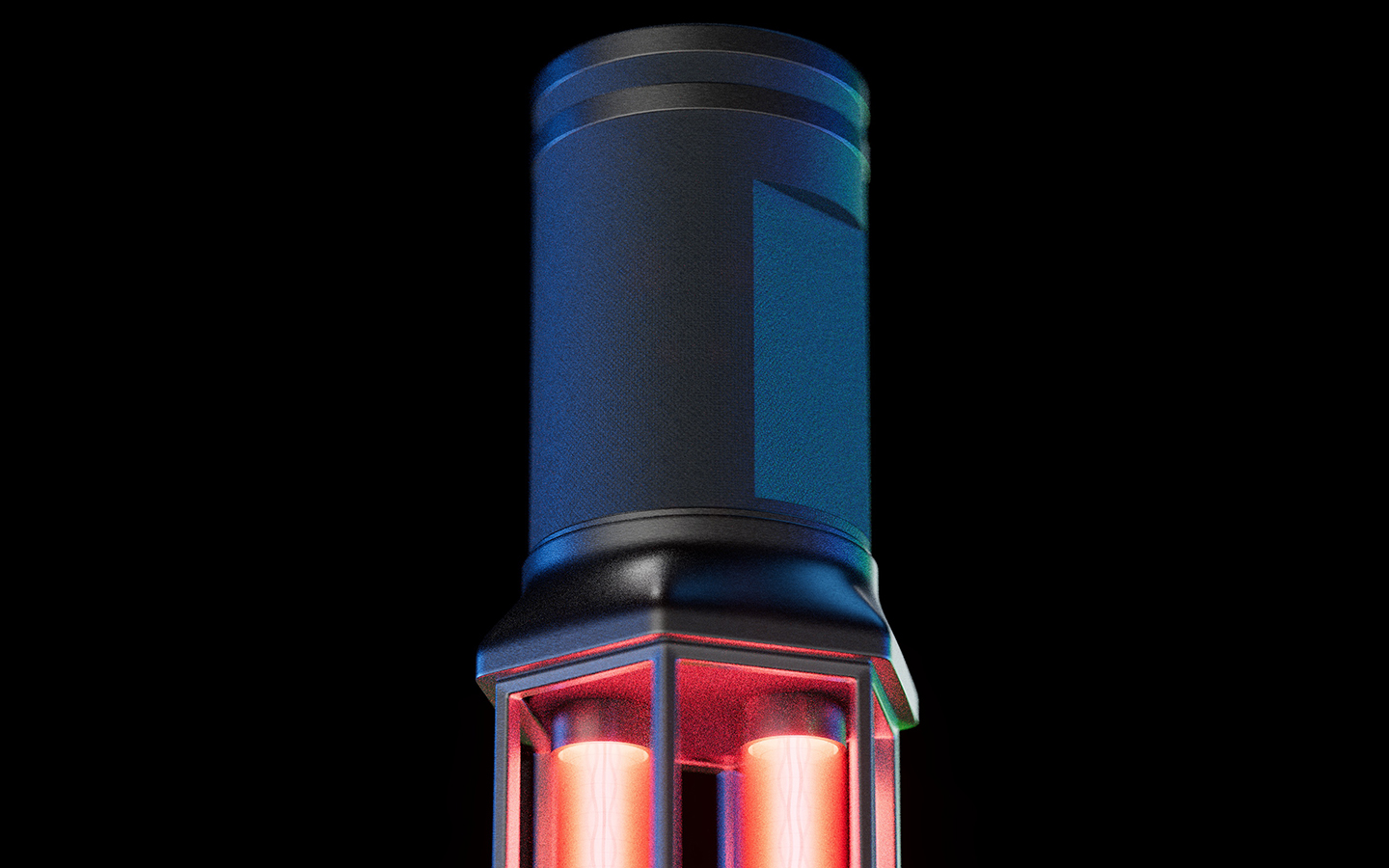

Design considerations for the nanophotonic laser are meticulous, focusing on factors such as the type and wavelength of the laser, power output, beam quality, and modulation control. Each parameter is fine-tuned to ensure the laser's effectiveness and precision during the writing process. The integration into the write head is a precise alignment endeavor, ensuring that the laser beam, delivered through the photonic funnel, is accurately focused on the recording media via the quantum antenna.

Thermal management is another critical aspect of the laser's design. Seagate has incorporated efficient cooling mechanisms to dissipate energy generated during the recording process, maintaining stability and reliability. These design optimizations are not merely about achieving higher areal densities; they ensure the Mozaic 3+ platform continues Seagate’s leadership in sustainable and reliable high-capacity data storage.

Photonic Funnel:

The photonic funnel is a waveguide that channels laser light directly to the quantum antenna with exacting accuracy. Its structure, a product of cutting-edge materials science and nanofabrication, is designed to confine the laser's path, preserving the integrity and power of the beam as it traverses to its target. The choice of materials is deliberate; a high refractive index is critical to guide the light efficiently, with minimal dispersion or loss.

Seagate's breakthrough in waveguide technology was not just in its material selection but also in its structural design. The geometry and dimensions of the photonic funnel are meticulously calculated to ensure efficient mode matching, a synergy between the light and the quantum antenna that maximizes energy transfer. This precision is not merely about controlling light—it's about intensifying the potential for data storage. By delivering a focused beam to heat the recording media at precise points, the funnel is instrumental in Seagate's ability to increase areal density, enabling more data to be stored within the same physical space of a hard disk drive.

High-volume production of this component has required Seagate to innovate beyond traditional methods. Thermal management strategies are integral to the funnel's design. Seagate's cooling mechanisms ensure the funnel operates within the optimal temperature range, maintaining stability and extending the longevity of the recording head.

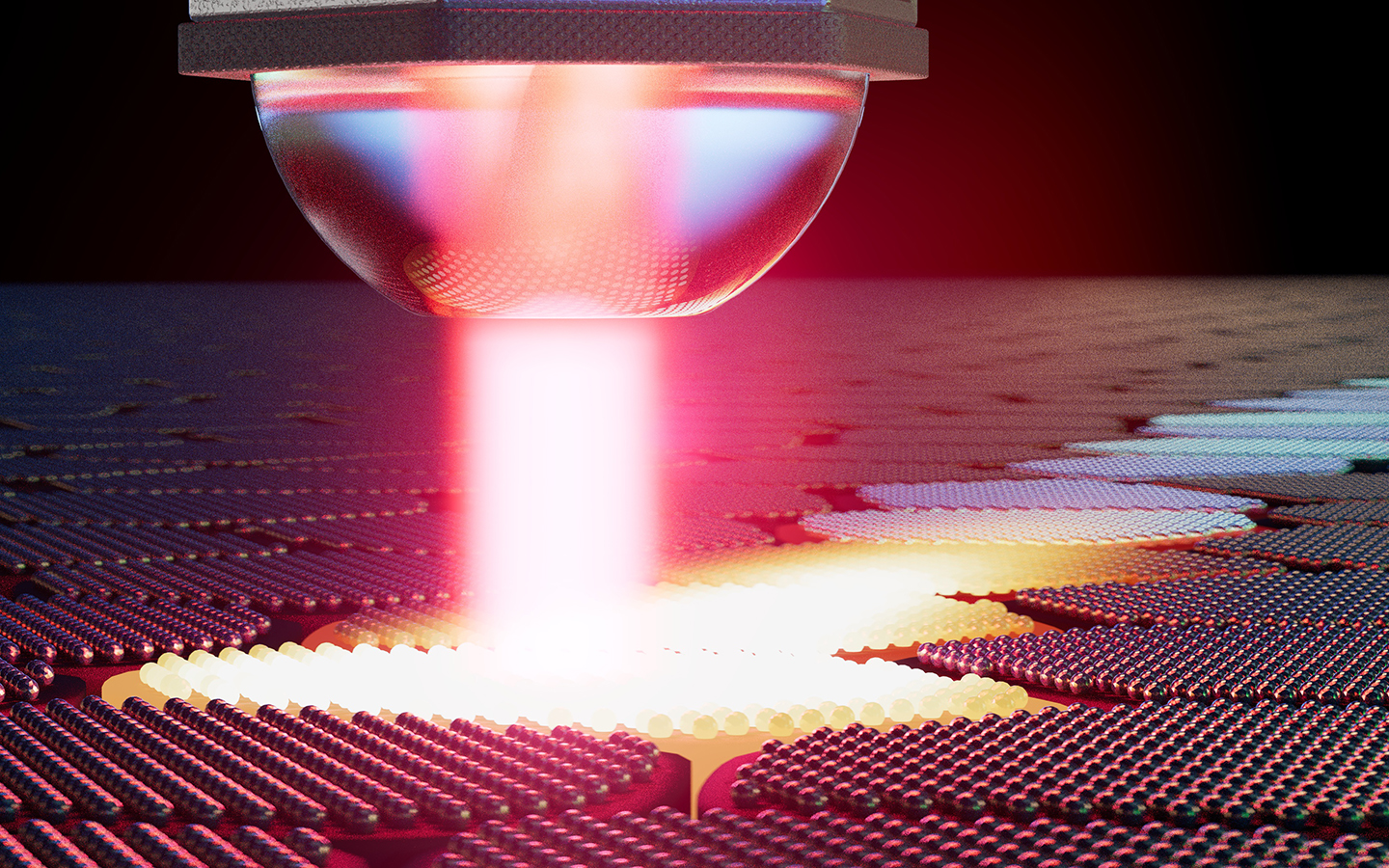

Quantum Antenna:

The quantum antenna, a brainchild of Seagate's engineers, is where the profound complexities of quantum physics and material sciences converge to enhance Mozaic’s recording capabilities.

Its primary function is to convert the laser energy into heat at an incredibly precise scale, enabling the platform’s high-density data writing. It does this through the generation of surface plasmons—quantum-level oscillations of electrons induced by light at the metal's surface. This conversion is highly localized, affecting only the area where data is written.

Seagate's development of the quantum antenna required innovation in several key areas. The antenna itself is a product of meticulous fabrication, made from materials selected for their optical absorption properties and ability to withstand the thermal rigors of the recording process. The focus on plasmonic properties allows the quantum antenna to effectively confine the laser's energy so that heating is concentrated and precise.

The integration of the quantum antenna within the write head assembly is a critical aspect of its design. It necessitates precision alignment to ensure the laser's energy is accurately focused on the recording media, enabling the pinpoint heating necessary for writing data one bit at a time.

The quantum antenna acts as a transducer, transforming the incident laser light into a high-intensity near-field electromagnetic field. This field is then used to locally heat the recording media above its Curie temperature, which reduces the coercivity of the magnetic bits and allows them to be realigned, thus writing data. The quantum antenna’s design enhances the coordination between the near-field energy from the laser and the magnetic field from the write head to ensure precision.

The design also incorporates advanced thermal management strategies. These are essential to ensure that the rapid heating and subsequent cooling occur with the required precision, preserving the integrity of the surrounding data and maintaining the overall stability of the storage process.

The quantum antenna is a key driver in achieving greater areal densities in hard drives. It represents a significant step forward from traditional recording technologies, with its ability to manipulate data at the nanoscale.

Enhancements to Areal Density

The collective operation of these plasmonic writer components leads to a substantial increase in areal density. By addressing the challenges of integrating a laser diode, precisely controlling the funnel, and optimizing the quantum antenna, Seagate's Mozaic 3+ technology can encode data more densely than any hard drive in history. This has been achieved through advancements in thermal management, materials engineering, and the miniaturization of components, reflecting a balance between innovation and practical implementation.

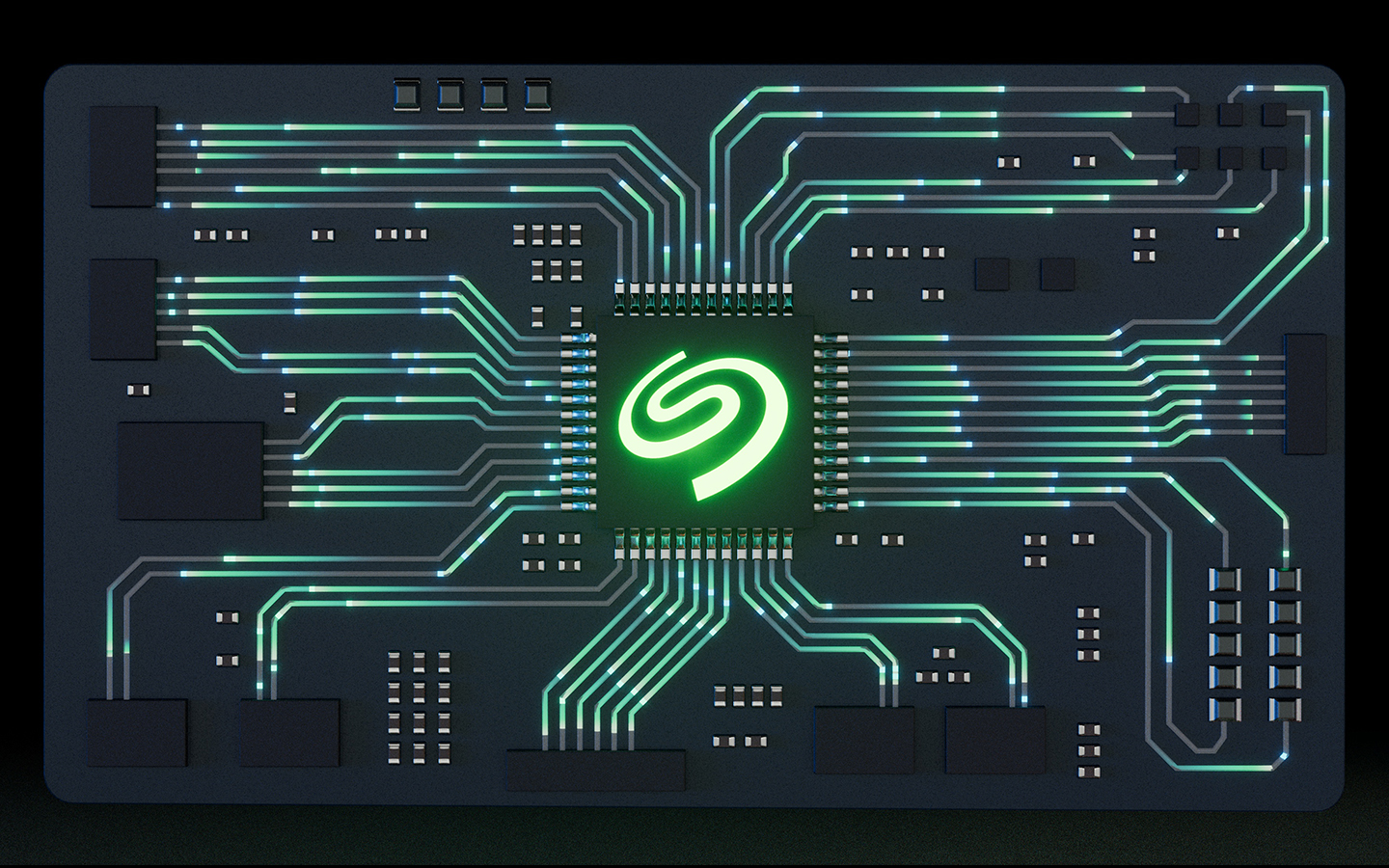

12nm Integrated Controller

The 12nm integrated controller’s role is multifaceted. Delivering this areal density at a large scale and compelling TCO requires a unique approach to the electronics controlling everything on the hard drive, from actuation to recording and security. This called for an integrated controller, a system-on-a-chip (SOC), developed entirely in-house by Seagate's silicon design experts.

The controller consolidates read channels, disk management, and data exchange protocols, becoming the operational heart of the hard drive. It controls spindle speeds, manages head movements, and executes read, write, and motion control with unprecedented precision. The integration of multiple functions onto a single silicon die is a testament to its sophistication. This tailored SoC is perfectly sized for the application and is optimized for specific calculations, speed, memory, and power efficiency to reduce waste.

The controller contains innovations like Seagate's own high-performance RISC-V CPU, the first RISC-V processor ever used to control hard drive functions, delivering up to three times the performance compared to prior solutions. This performance leap enables the advanced algorithms that help deliver increased areal density.

Recording improvements include Automated Multi-Rev Recovery (AMRR), which automates high-impact data recovery operations, automated Adjacent Track Interference Cancellation (ATIC), and enhanced Iterative Outer Code (IOC), combining the correction power of LDPC decoding with Track-based ECC.

A critical feature of the 12nm integrated controller is its servo core, designed to target data tracks with greater precision. The processor's refined microarchitecture, combined with targeted instruction-specific latency reduction, enables enhanced performance in essential servo workloads. This includes real-time handling of disturbance detection, adaptive control features, feed-forward compensation, and high sample-rate computation. The processor can take less than half the time to execute the same amount of work as previous processors—and that’s important, because of the need to make rapid real-time adjustments to the servo to keep the actuator on the incredibly narrow data track.

As hard drives now feature over a million tracks per inch, even ambient sounds could threaten the actuator’s accuracy. Seagate's servo-processor, operating at picosecond intervals, processes up to 4 billion bits every second, executing complex algorithms to counteract potential disturbances and maintain the drive's tracking accuracy by effecting the exact movements required for the tri-stage actuators of the drive heads.

Seagate's controller includes a fully custom read channel analog front-end that samples at rates exceeding 4Ghz, equating to a new sample every quarter of a nanosecond. These processing enhancements do not compromise power efficiency.

The transition from a 28nm chip to a 12nm chip is another leap forward, enabling lower die costs and power consumption. This shift in process technology is crucial for accommodating more transistors within the same chip area, reducing voltage requirements, and offering an improved power profile.

The RISC-V architecture plays a pivotal role, offering customization that facilitates application-specific computational tasks, including simulations and machine learning model training. Moreover, the use of open security architectures paves the way for secure data movement, a significant consideration in today's data-centric landscape.

Additionally, modifications specific to Mozaic 3+ such as 'Mode-hop' mitigation further bolster the drive's reliability and performance, ensuring Seagate’s flagship enterprise hard drives retain the edge among high-density storage solutions.

By centralizing the entire stack, from design to fab, Seagate ensures direct control over the integration and performance of its silicon, setting it apart as the sole hard drive manufacturer with such capabilities.

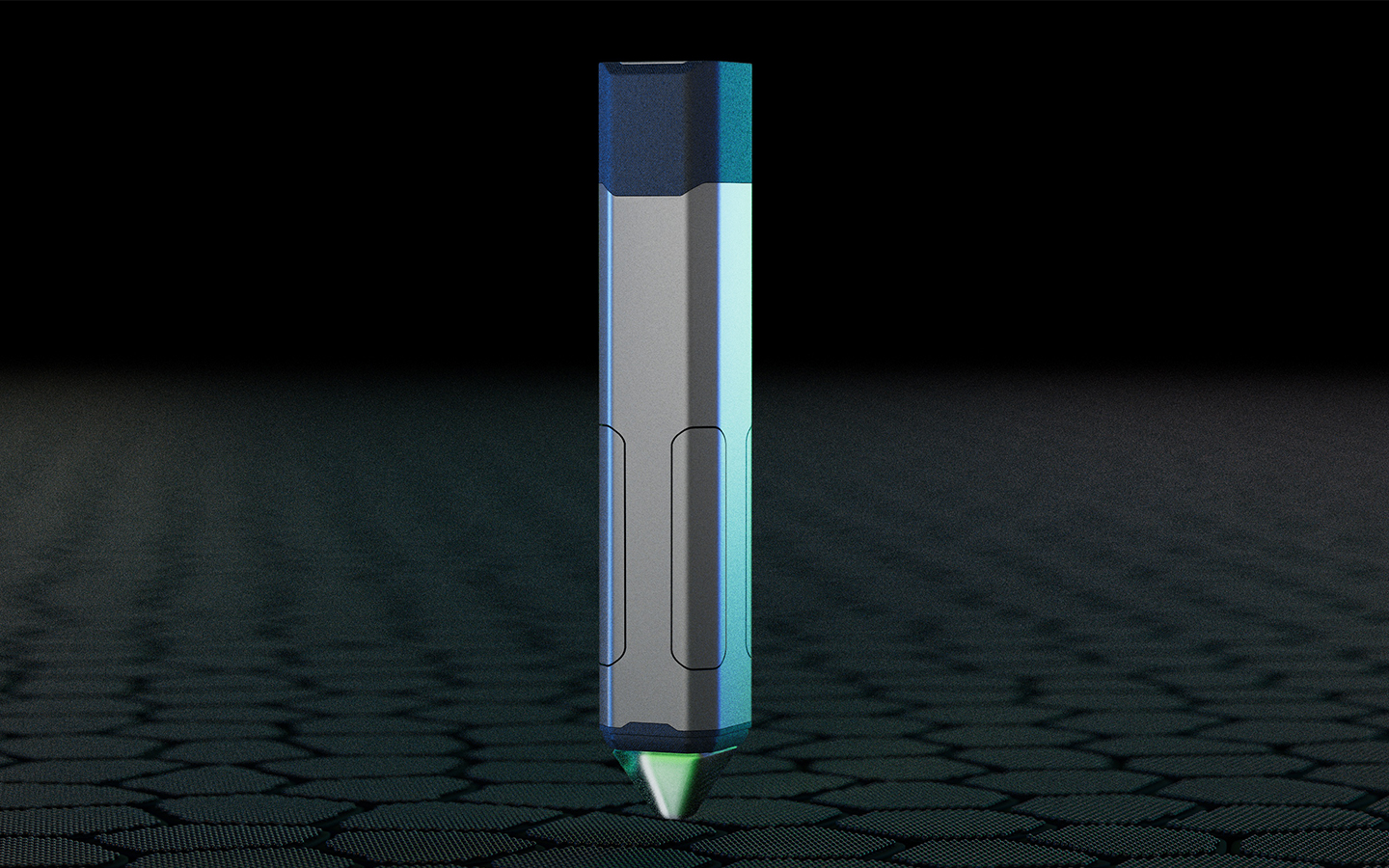

Gen 7 Spintronic Reader

Smaller grains of written data are only useful if they can be read. Integrated along with the sub-components of the plasmonic writer, the reader also needed to evolve. Incorporating quantum technology, Mozaic 3+ includes one of the world's smallest and most sensitive magnetic field reading sensors, the Gen 7 spintronic reader.

A key feature of the Gen 7 spintronic reader is its very narrow track width, which ensures precise reading from the intended track while minimizing crosstalk from neighboring tracks.

At its core, the reader relies on the tunneling magnetoresistance effect—a quantum mechanical phenomenon where the electrical resistance of a magnetic tunnel junction (MTJ) changes depending on the relative orientation of magnetic layers separated by an insulating barrier. The reader's design ensures high-resolution magnetic readback, minimizing inter-track interference, which is vital for accurately reading the smaller and more densely packed recorded bits in Mozaic 3+ drives compared to traditional hard drives.

The reader includes a complex stack of layers integrated into the read head assembly. This stack comprises various magnetic and non-magnetic layers, each playing a specific role in the readback process. The layers work collaboratively to convert the magnetic signals from recorded bits into electrical signals, which are then processed and decoded to retrieve stored data.

The magnetic stack's composition and properties are meticulously selected to deliver optimal performance. The magnetic layers include the free layer (FL), which is sensitive to external magnetic fields from recorded data; the reference layer (RL), which maintains a stable magnetic orientation; and the synthetic antiferromagnet (SAF), acting as a buffer to prevent the RL's magnetic orientation from influencing the FL.

To prepare the reader stack for Mozaic 3+ technology, materials and layer thicknesses are selected for their thermal stability to withstand the temperature fluctuations during the write process. The tunnel junction's barrier layer, made of magnesium oxide (MgO), is subject to controlled oxidation to adjust the reader's sensitivity and effectiveness.

The reader's stack is constructed using a multiple-chamber deposition process under continuous vacuum conditions to prevent contamination. The precision required during the layering process demands exact controls over the thickness of each layer, which is crucial for the reader's performance.

Seagate's innovative stack design optimizes the sensitivity and signal-to-noise ratio, enabling accurate readback from Seagate’s superlattice platinum-alloy media and facilitates higher data densities in Mozaic 3+ hard drives.

Beyond Cloud: The Future for All Data-Hungry Applications

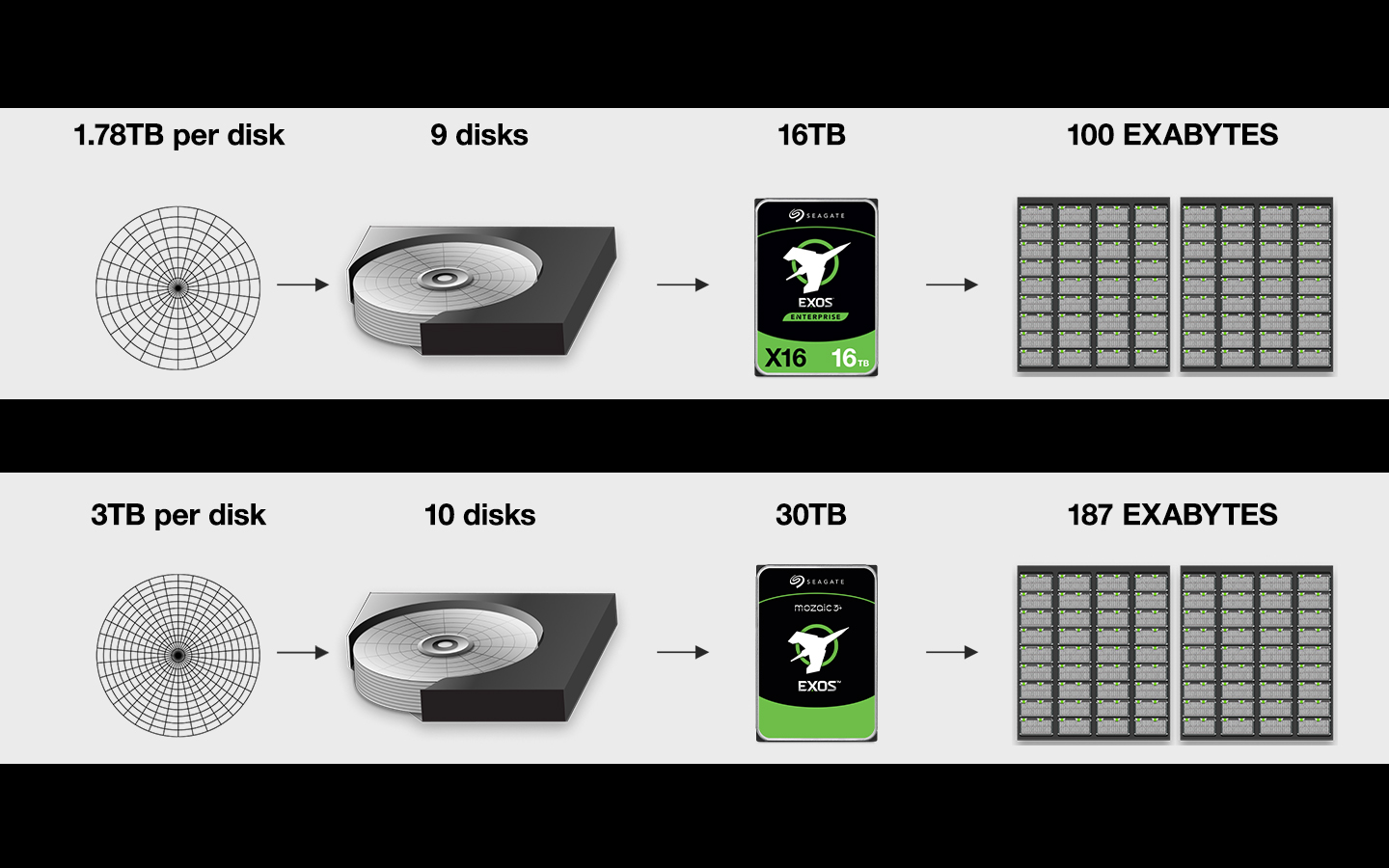

Seagate's Mozaic 3+ technology will play a pivotal role in meeting the escalating demands of data-intensive applications. The push for higher areal density is fueled by the exponential creation of data across multiple sectors, from enterprise to cloud data centers, necessitating more efficient and cost-effective data storage solutions.

Data-hungry applications that will benefit from areal density advancements include machine learning models requiring vast datasets for training, video streaming services that need to store and deliver 4K and 8K content, and medical research databases that accumulate large-scale genomic sequences.

Seagate's Mozaic 3+ platform is poised to deliver these advancements not just for hyperscale and cloud data centers but across a spectrum of storage products.

As the technology is integrated over time into Seagate's diverse hard drive families—like IronWolf Pro, SkyHawk, and Exos—the benefits will permeate through various applications, from multicloud and hybrid cloud environments to high-capacity and mid-range capacity storage needs. Data-heavy applications of all kinds will increasingly rely on the efficient, high-capacity solutions that only Mozaic 3+ enables.

But Mozaic 3+ is more than a technological advance—it’s a promise to sustain the inexorable growth of the digital universe. The platform’s areal density technologies will be fundamental in sustaining the continued growth of data-intensive applications, underpinning the development of new services and the expansion of existing ones.

As we look to the future, the capacity to store, access, and leverage vast quantities of data will be integral to driving innovation and harnessing the full potential of the digital age. With the introduction of Mozaic 3+, Seagate isn’t just keeping pace with the data explosion—it’s setting the tempo, driving the advancement of storage solutions towards a horizon where data's potential is limitless.